Updating Fan and Control Technologies in 40-year-old Office Building Reduces Energy Costs 26%

At A Glance

Replacing the heart of an air handling system in a commercial office building with better fan and control technologies can significantly reduce energy costs while dramatically improving equipment uptime. It also goes a long way to reduce maintenance costs and resolve nagging reliability challenges. This is the Blue Cross Blue Shield (BCBS) of Downtown Kansas City, MO story about how it took steps to improve office worker productivity by transforming its air handling systems. BCBS operates in an eight-story office building that is home to hundreds of employees and serves as the headquarters for Kansas City BCBS.

Photo: Example of an old vaneaxial fan, where components like the motor are difficult to service or replace. These fans often require lengthy sound attenuators to reduce fan sound.

“At some point, technology updates lead a facility to make a change in order to update and improve their system. Now was our time and a FANWALL system was our solution.”

Equipment

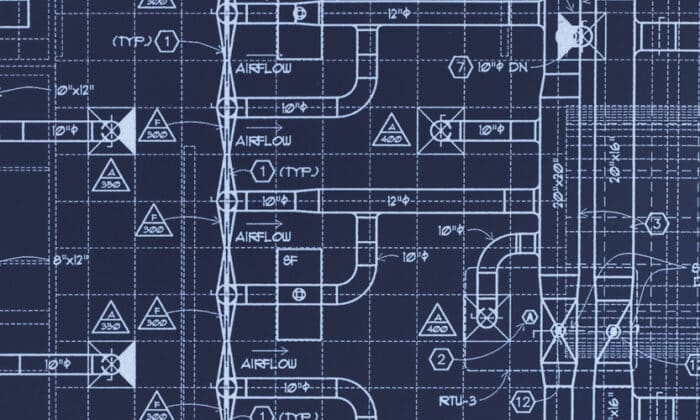

The FANWALL arrays are designed to be installed in a wide variety of configurations. In the BCBS building, the design called for two sets of 12 cubes in a 3×4 configuration within the existing penthouse air handlers on the supply airside, and two sets of 12 cubes in a 3×4 configuration on the return airside.

The FANWALL array retrofit work took place in December 2013 over a two-week window during the holiday. The actual time that was needed to demo the old equipment, rig the new equipment to the roof, install and start up the new FANWALL systems was an astonishing four days. This four-day window also included other air-tunnel upgrades.

“The ease of the modular design allowed us to mobilize much quicker and with less rigging time to help keep the estimate down.”

KEY POINTS

- Facing frequent fan failures, the owner of the Blue Cross Blue Shield office building in Kansas City, MO, needed to replace the fans in two aging air handlers.

- The owner wanted to improve both system reliability and energy efficiency.

- Multiple fan FANWALL arrays were used to replace the existing fans. The solution resulted in significant energy savings and improved system reliability.