Energy Efficiency

- Ultra-high efficiency Permanent Magnet (PM) Motors have proven to be 5% to 20% more efficient compared to NEMA Premium® efficiency induction motors. Try our interactive payback calculator here.

- Variable Frequency Drives (VFD) enable individual on/off and speed control of fans to maintain peak static efficiency and pressure over the air handler operating range.

- Fans come in 8 sizes from 10 – 27 inches to match performance requirements and optimize operation efficiency.

Quiet Operation

- High-performance polymer fans have an aerodynamic shaping of the blades, shroud, and cones, while the material provides damping to reduce sound tones from the impeller and motor.

- Coplanar Silencer® is a patented enclosure for FANWALL cubes. The cubes are lined with perforated steel and acoustic insulation to provide up to an 18 dB reduction in discharge sound power.

Redundancy and Reliability

- If a fan or motor failure occurs in a FANWALL system, the remaining operating fans can compensate to maintain airflow and static pressure until the failed component(s) can be repaired or replaced.

- Dedicated VFD for each fan and motor combination. A fan, motor, or VFD failure is inherently isolated, eliminating the need for a bypass VFD or potential for a ground fault failure of the entire array.

Easy Installation

- Ideal for installation where space or access is limited, especially as retrofit or replacement. Overall air handler length can be reduced by 30% – 70% using a FANWALL system.

- Single-point power connection to all VFDs speeds installation.

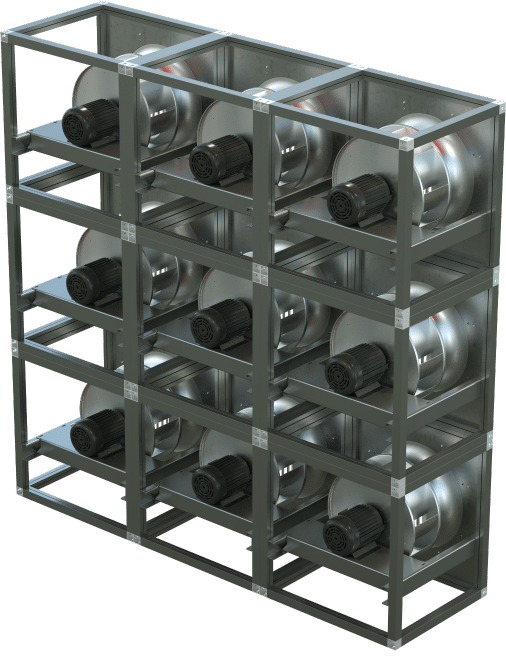

- FANWALL cubes can be arranged in many different combinations to suit the space available.

Flexible Configurations

- Both AMCA Certified™ stainless steel fans and high-performance polymer fans are available in multiple sizes to efficiently meet system performance or application requirements.

- Choice of motors to meet project efficiency requirements, including induction, PM, and ECMI.

Advanced Engineered Design

- Variable cube dimensioning allows the selected array to more closely fit air tunnel dimensions, so that the fans produce a uniform piston of air over the entire coil surface for optimal heat transfer and even filter loading.

- System optimization controls allow on/off control of individual fan cubes to match requirements in variable airflow applications with the optimum number of fans and motors operating at peak efficiency.

- FANWALL backdraft damper seals off the fan to prevent recirculation of system air with very little leakage if a cube is taken out of operation. When open, the damper’s aerodynamic design ensures almost zero-system effect.

- Stringent balance requirements and sturdy components in each FANWALL cube eliminate internal vibration and the need to isolate a FANWALL array within the air handler. It can also help eliminate the need for a concrete inertia pad for the air handler and facilitate meeting requirements for seismic certification.

- The need for sound attenuators and other ancillary components that create a static-pressure penalty within the air handler can be eliminated.

Low Maintenance and Service

- FANWALL systems eliminate belts and sheaves, because they use direct-drive fans instead of belt-driven fans.

- Permanently sealed motor bearings provide long life and require little-to-no maintenance.

- Components in a FANWALL system typically are significantly smaller, lighter weight, and easier to access than the same components for conventional fan systems.