Improving Air Handler Reliability at Carolinas Medical Center

FANWALL® Arrays Offer Superior Reliability and Efficiency in Carolinas Medical Center

At A Glance

Replacing the heart of an air handling system with better fan and control technology saved a healthcare facility more than $103,469 per year. Just as importantly, it permanently resolved nagging reliability challenges. Carolinas Medical Center (CMC) in Charlotte, North Carolina, is the flagship hospital of Carolinas Healthcare System, one of the nation’s largest healthcare organizations.

Its day-surgery facility on Blythe Boulevard is a key element in the Center’s operations. The building is owned by CMC with property management by Lincoln Harris, a major property owner and manager in the Carolinas. The building was served by two penthouse air handlers, each equipped with two vaneaxial fans, one each on the supply and return air sides.

“We could not be happier with our decision to have installed FANWALL into critical air handling units."

Equipment

Transforming How They Move Air

TRS developed a proposed design to replace the vaneaxial fans using four arrays of FANWALL TECHNOLOGY® modular fan cubes, together with System Optimization Controls (SOC) for the arrays.

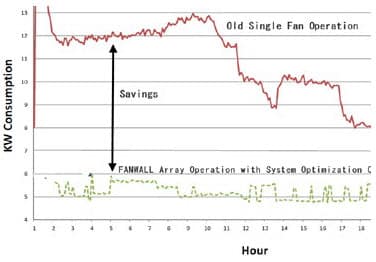

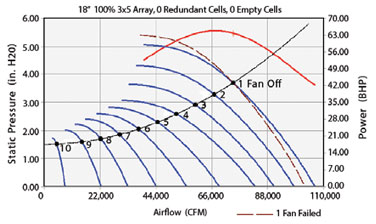

Jeff Forman, Vice President and General Manager of Governair®, comments on this approach. “We see increasing numbers of building owners and designers recognizing the benefits and capturing the energy savings with multiple fan arrays in air handling systems, especially in critical environmental situations.” He points out the particular value of System Optimization Controls. “With SOC we can vary the speed of fans and turn off fans when not needed, which leaves the remaining fans operating near their peak efficiencies. There are tremendous energy savings in operating this way. Each of the motors has its own variable frequency drive, so if one fan were to become disabled, the remaining fans can speed up to overcome the loss in airflow.”

The contracts for the project were let in late 2011. It was understood that the ideal time to do the air handler changeover was in the winter, when cooling requirements were lower and the four existing fan units could be taken out, one at a time. The contractor selected to execute the project was McKenney’s, Inc., a large mechanical contractor with offices in Atlanta and Charlotte.

Fit in Existing Air Handler

The FANWALL units are designed to be installed in a wide variety of configurations. In the CMC building, the design called for two sets of 15 cubes in a five-wide, three-high configuration within the existing penthouse air handlers on the supply airside and two sets of 12 cubes four-wide and three-high on the return airside.

Individual cubes on the supply side are 34″ wide by 38″ high, so getting them into a tight work area is seldom a problem. According to Hall, a crane lift to the rooftop was used for speed and ease of fan and sheet metal removal. Normally the cubes are brought in through a standard doorway.

The installation work took place in January and February of 2012, at a time of year when it was practical to take the old fans out of service one at a time. The contractor took out one set of fans first, keeping the other fans operating. But the old fans were held on site in the event one of the other vaneaxial fans went down and repair crews had to scavenge parts to bring it back on line.

KEY POINTS

- Outdated vaneaxial fans were replaced with FANWALL arrays to improve system reliability, performance, and energy efficiency.

- The new FANWALL arrays saved the hospital 1,480,240 kWh or $103,469 in energy costs during the first year of operation, while increasing airflow capacity from 124,000 cfm to 149,000 cfm.

- The new system is redundant and reliable, and the System Optimization Controls (SOC) rebalance the system and take up the slack if a unit is lost.