Dell Children’s Medical Center

First Hospital to Achieve LEED® - Platinum Certification

At A Glance

When Dell Children’s Medical Center began the development of its new facility in Austin, Texas, the organization established a compelling vision: to heal children without harming the environment. That’s no easy task for a power-intensive industry like healthcare.

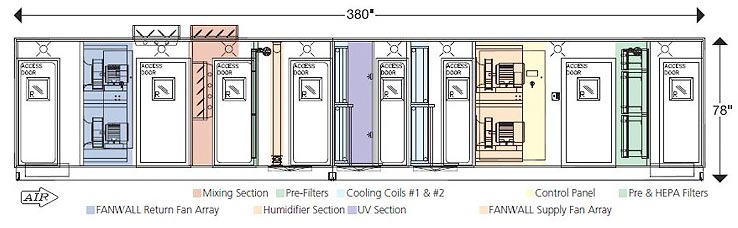

The 500,000 square foot facility that opened in July 2007 achieved its mission through sustainable design, green materials and energy-efficient systems. Air handlers from Nortek Air Solutions supported the organization’s green initiatives. In addition, Dell Children’s Medical Center recently installed a Semi Custom unit with FANWALL TECHNOLOGY that manages critical ventilation in a 6,500-square-foot intra-operative MRI surgical area.

In March 2009, the U.S. Green Building Council recognized Dell Children’s Medical Center with LEED -Platinum certification, the highest of its four achievement levels for Leadership in Energy and Environmental Design. The facility is the world’s first LEED -Platinum hospital.

“If you’re looking for redundancy, reliability and a great acoustic result all rolled into one, that’s a FANWALL system every time.”

- Rusty Vaughn of Texas AirSystems, Dallas

Equipment

Four Fans Achieve 100% of Future Capacity

“Chief considerations for the Dell Children’s project — and for many healthcare facilities — were adequate redundancy for the operating rooms, acoustical performance and capacity for future expansion,” explains Meers.

“With a traditional unit, to achieve 100% redundancy requires a really big box,” he says. “With FANWALL TECHNOLOGY, because you’re using direct drive fans, you only need 25% of the size as a backup, and that takes a much smaller footprint.”

The new Dell Children’s installation serves an intra-operative MRI operating room and a diagnostic MRI room, with additional “shell” space for future needs. The current project requires approximately 9,000 cfm, enabling the hospital to easily expand without the expense of adding or replacing its air handlers.

“We have four fans, but we only need to run three at any time,” Meers says. “The advantage of multiple fans is that unlike bigger units, the FANWALL array can be sized for 100% of future capacity. We handle hospital projects all over the country, and that’s a common need.”

FANWALL’s quiet acoustical performance also supports the sensitive medical technology to be housed in the new wing, which can be disrupted by intensive vibrations. “The FANWALL is quiet — hardly noticeable,” adds Risner.

KEY POINTS

- Nortek Air Solutions partners with The Dell Children’s Medical Center in Austin, TX to build the world’s first LEED - Platinum Certified hospital.

- A Custom Air Handler with FANWALL TECHNOLOGY was used to provide ventilation to a 6,500 sq. ft. MRI operating suite.

- Air quality, green design, acoustic considerations, and size constraints were primary factors.