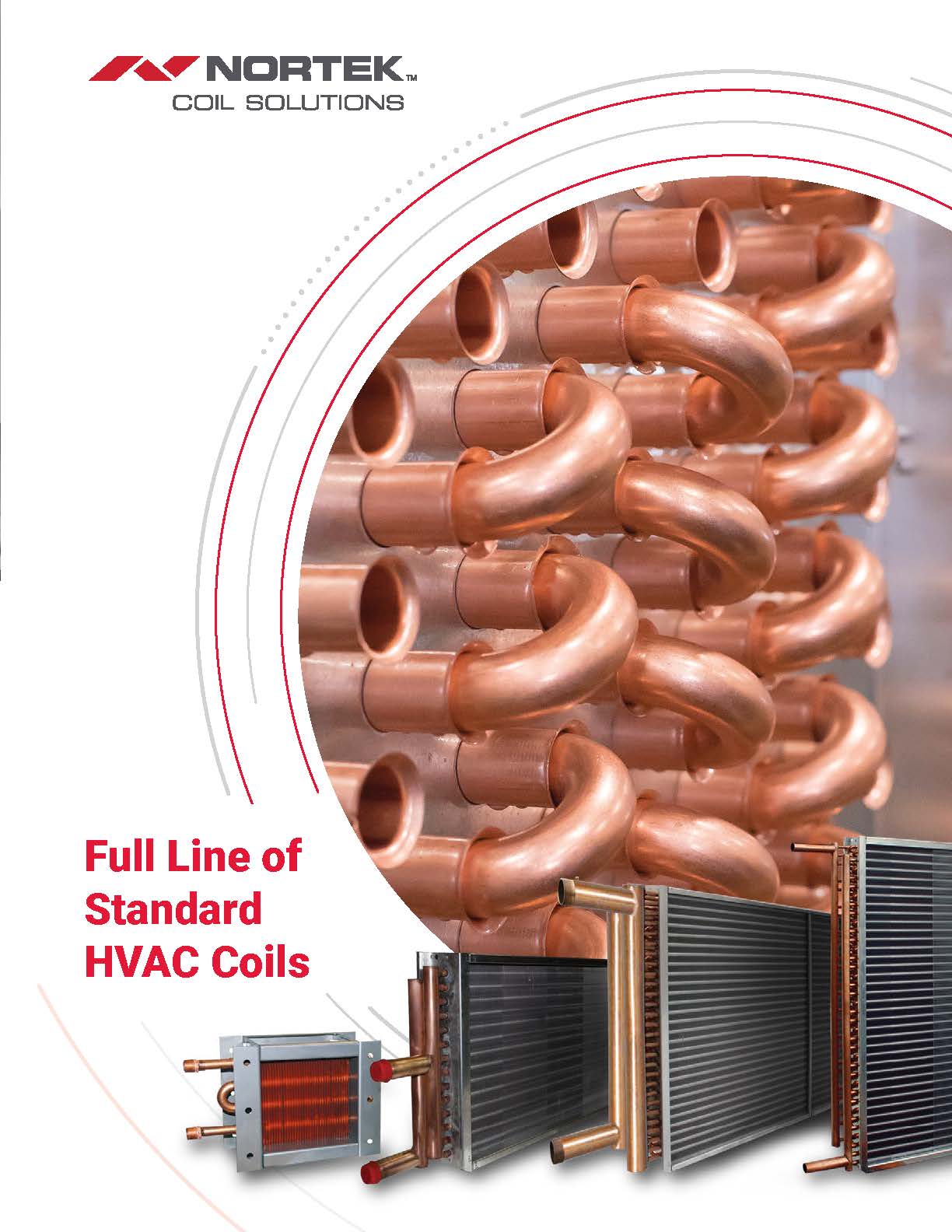

A Full Line of OEM & Replacement Coils

We offer a full line of hot and chilled water, steam, booster, and direct expansion (DX) replacement coils for your air handling system. Our expertise, attention to detail, and high standards go into each coil we manufacture. Our coils are made of the highest-quality materials, manufactured under strict quality control standard, and designed for long life and top performance.

REPLACEMENT COILS

Replacement coils we offer:

- Water coils for cooling, heating, and general heat transfer applications

with water or thermal fluids such as ethylene or propylene glycol. - Steam coils for heating and drying applications. We offer standard steam coils or steam distribution coil types.

- Booster coils for duct mounting and low-flow applications.

- Direct expansion (DX) evaporator coils for air conditioning and dehumidification applications. For use with a variety of refrigerants.

Timing is critical when your air handling system is down. We can deliver the right coil quickly to have you back up and running as fast as possible. Contact us when you need replacement coils in days rather than weeks.

Call 833-627-3645.

Blank Coil Drawings:

- DX Evaporator Coils

- Intermediate Drain Headers – Water Coils

- Steam Distributing and Standard Steam Coils – Opposite End

- Standard Steam Coils – Same End

- Steam Distributing Coils – Dual Supply

- Steam Distributing and Standard Steam Coils – Same End

- Steam Distributing Coils – Opposite End

- Water Coils – Collection Header

- Water Coils – Opposite End

- Water Coils – Same End

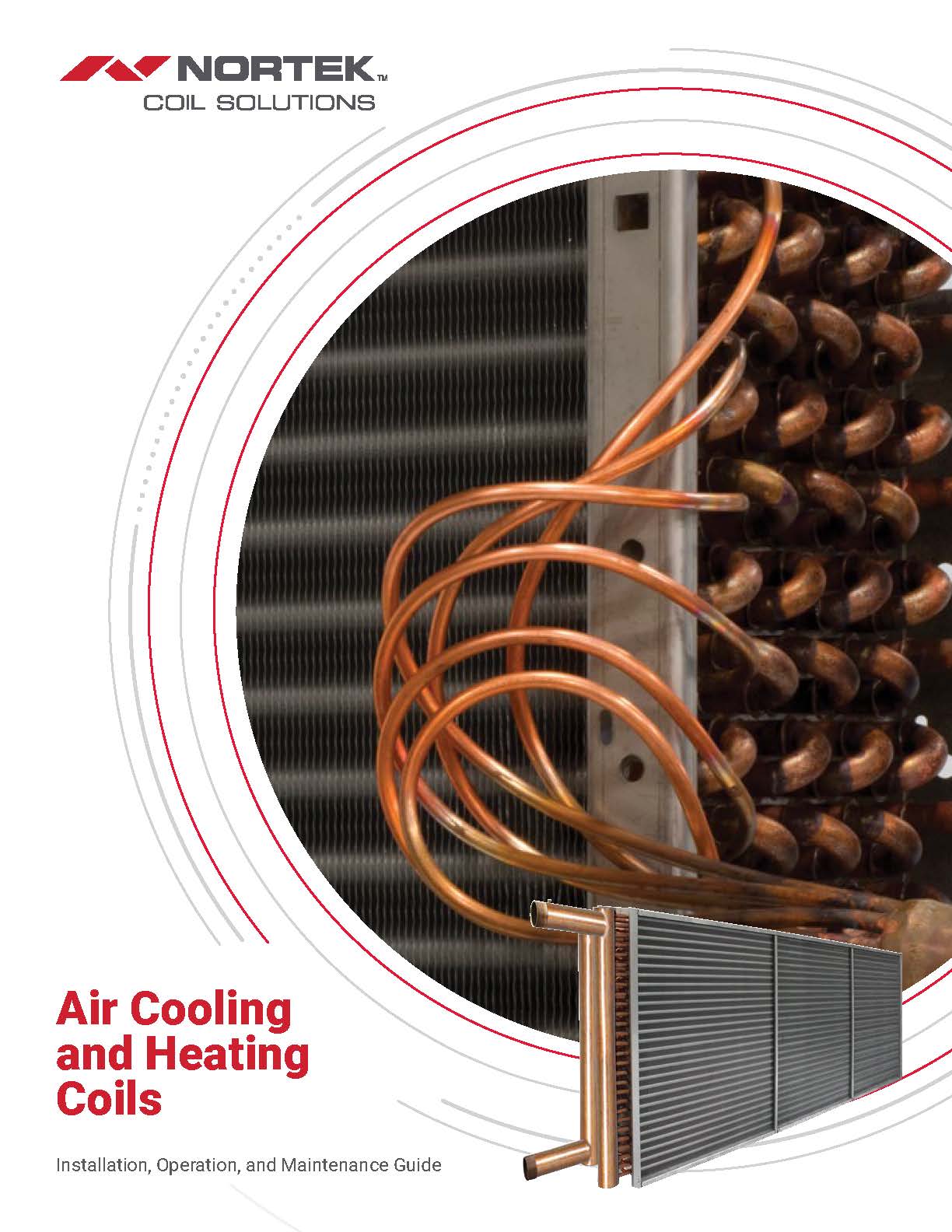

Benefits & features

High-quality Manufacturing

Coil tubes are round, seamless copper which mechanically expand into the fin collars, providing a permanent metal-to-metal bond for efficient heat transfer.

Coil tubes are staggered in direction of airflow.

Fin collars are fully drawn to provide accurate control of spacing and maximum contact with the tubes.

Headers are seamless copper with die-formed holes that provide a parallel surface to the tube for strong brazing joints.

Coils are submerged under water and then pressurized with air to check for leaks.

Certified Performance

AHRI Certified™ to Standard 410 — giving you the confidence that your coils will perform as promised.

AHRI Certified™ coil performance can be useful during verification for LEED® or other building certification programs.

Flexibility

Variable casing dimensions, fin spacing, copper tube thickness, and a variety of casing and fin materials, including copper fin and stainless steel casings for coils in corrosive atmospheres.

Protective coatings and treatments available to extend the service life of coils installed in corrosive atmospheres — fins, tubes, headers, and casing are completely coated.