Fan Systems for New Construction and Replacement Applications

Using our FANWALL Systems to replace aging, end-of-life fans in existing air handlers can be the most cost-effective solution for avoiding the cost and business disruption of an air handler failure while delivering energy savings as high as 40%. Featuring our innovative FANWALL TECHNOLOGY®, FANWALL Systems are ideal for replacement applications with access or time limitations, without requiring a major demolition and reconstruction project.

Ideal for New Construction & Retrofits

FANWALL Systems are also a great solution for new construction. Consisting of an integrated system of state-of-the-art fans, motors, cabinetry, controls, and accessories matched to your air handling requirements, our FANWALL Systems have become the preferred choice for engineers, contractors, and building owners valuing redundancy, quiet and vibration-free operation, optimized energy efficiency, and low-cost maintenance.

Benefits

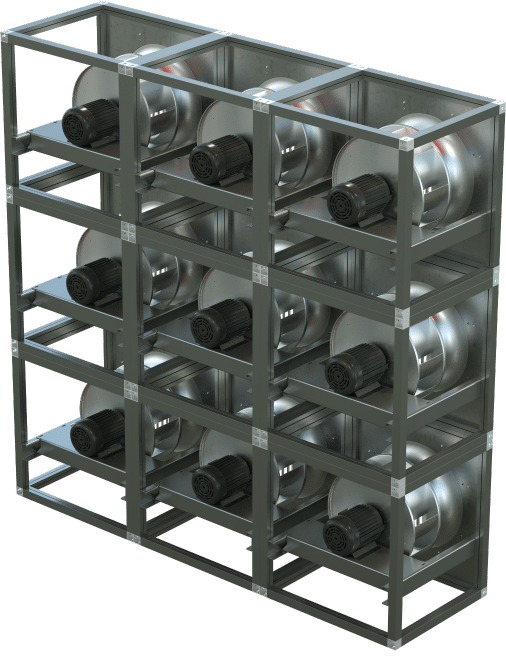

High-Efficiency

Fans

Direct-drive fans come in 7 sizes, from 10 to 27 inches, to match your application requirements

Available with Incremental Horsepower High-Efficiency Motors or Ultra-High Efficiency Permanent Magnet (PM) Motors

LOW SOUND LEVELS AND VIBRATION

Patented Coplanar Silencer® enclosure reduces discharge sound power by as much as 18 dB.

Designed to eliminate vibration at the source through stringent balance requirements and the use of sturdy components

RELIABILITY THROUGH REDUNDANCY

If one fan fails, only that portion of the airflow is lost, unlike single fan systems where the entire air handler goes offline

Loss of airflow from one fan can be offset by increasing the speed on the remaining fans

COMPACT, MODULAR DESIGN

Fan Cubes can fit through a standard 3-foot door for applications with access restrictions.

There is no need to have a crane on site as is often the case with larger, more conventional fans.

OPTIMIZED PERFORMANCE

Variable cube dimensions allow you to match your fan array to fit air tunnel dimensions.

On/off control of individual fan cubes to closely match requirements in variable airflow applications with the optimum number of fans and motors operating at peak efficiency.

Eliminate components that require routine maintenance and degrade performance over time.