Precise Environmental Control for Indoor Agriculture

Successful indoor agriculture is dependent upon precise environmental control for successful crop growth, crop yields, crop quality and resistance to disease and any unforeseen stresses. Environmental controls include acceptable indoor humidity levels. Plants that are cultivated indoors are sensitive to the amount of moisture in the air throughout each stage of their growing cycle.

Also, managing HVAC systems in natatoriums (indoor swimming pools) presents several unique challenges due to the specific environmental conditions and requirements, especially in humidity control, temperature regulation and air quality.

Indoor Agriculture HVAC Challenges

-

Temperature Control

-

Humidity Management

-

Air Quality

-

Energy Efficiency

-

System Integration

-

Scalability

-

Regulatory Compliance

Temperature & Humidity Control…

…are crucial for plant health and growth. Fluctuations can stress plants and affect yields. Grow lights generate significant heat, requiring robust cooling systems to prevent overheating. Air filtration systems are essential to remove contaminants and odors, which can affect plant health and the working environment. Nortek Air Solutions has the products to help you address the most challenging environments.

Precise Environmental Control…

…is often needed for different stages of plant growth requiring specific humidity levels. High humidity can lead to mold and mildew, while low humidity can stress plants. Effective dehumidification systems are necessary to manage the moisture produced by plants and irrigation. Nortek Air Solutions packaged DX products can provide your precise environmental control.

Packaged DX Simplicity

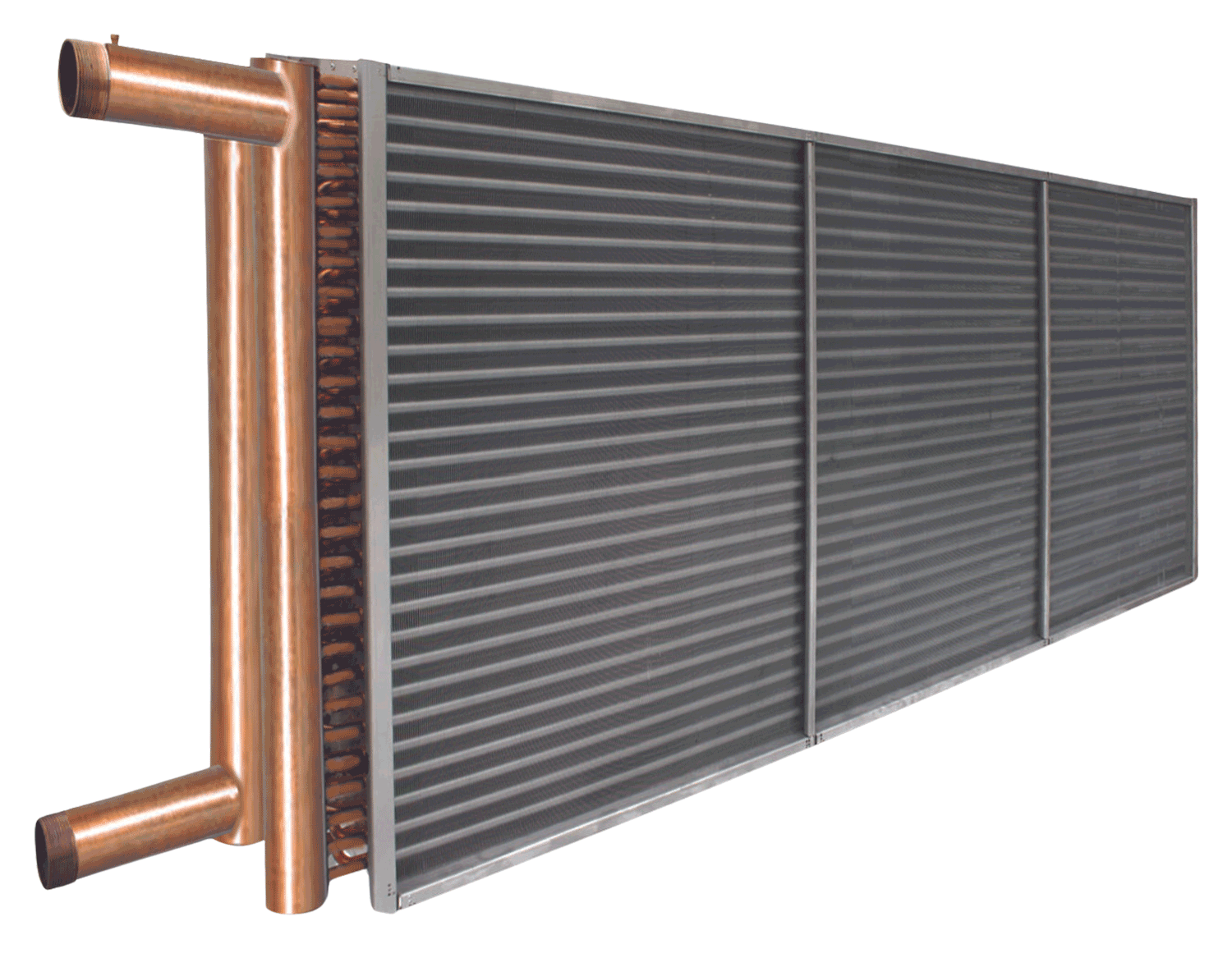

Nortek Air Solutions offers a full line of DX coils that meet any demand or application. The DX coils come in 3-,4-,6- and 8- row configurations. These DX coils can be combined with additional components that offer further or extra capabilities such as heat recovery devices in low ambient applications. The configurations can be provided with a hot gas reheat coil for dehumidification capabilities and modulating compressors for precise comfort control.

Energy Efficiency and Reliability…

…go hand in hand with FANWALL TECHNOLOGY. Balancing temperature control with energy efficiency to minimize operational costs. A FANWALL array of fans can be modulated with a variable frequency drive to match the operating conditions. Fans can be turned off when conditions require less air. Nothing saves energy like a fan that is off. Our system optimization controls can provide the automatic management of airflow to maximize energy savings.

Scale…

…is the manufacturing competency Nortek Air Solutions excels in. Unique dimensions are one reason customers seek a custom solution. We offer custom sizes ranging from very small 2000 CFM to over 400,000 CFM, and 20 to 400 tons, with complex configurations (double/triple wide, double/triple stack, L-shaped, U-shaped).

Factory Mounted Controls…

…on packaged DX air handlers provide stand-alone controls for custom applications. They are designed to provide optimized and reliable management of unit operation and energy recovery processes. And they easily interface with building management systems (BMS). Programmed and tested to industry standards, these controls achieve the best cost-effective solutions in meeting the requirements of building management applications.

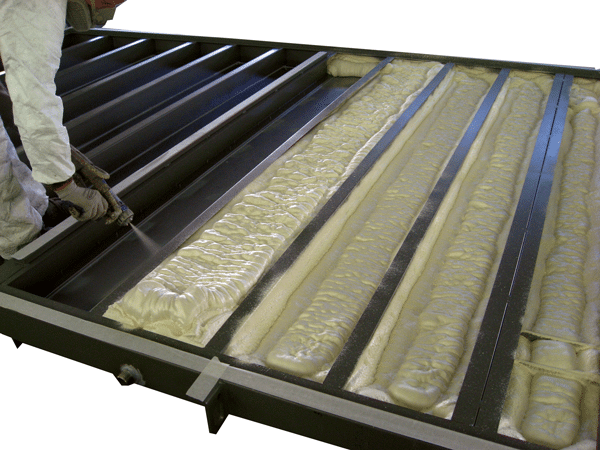

Advanced Thermal Break Technology…

…helps protect your investment by insulating the cool air tunnel of an air handler from the warmer exterior cabinet temperature to help prevent condensation from forming. If not managed, the water produced from condensation off the exterior of the unit can be significant and damaging.

Evaporative Cooling

Many plants thrive in environments with higher humidity. Evaporative cooling is crucial in greenhouses for this reason. As warm air from outside the building is drawn through a wet media, the water evaporates, cooling the air. It helps maintain optimal temperature/humidity levels, especially during hot weather. Reducing the indoor temperature can reduce plant heat stress, which can negatively impact growth and productivity.