Fan Systems for New Construction and Replacement Applications

Using our fan systems to replace aging, end-of-life fans in existing air handlers can be the most cost-effective way to avoid an unexpected air handler failure, while delivering energy savings as high as 40%. Choose from four fan options: a FANWALL system, AcoustiFLO™ fans, FANWALL EC, or the PF09. Featuring our innovative FANWALL TECHNOLOGY®, FANWALL systems are ideal for replacement applications with access or time limitations, without requiring a major demolition and reconstruction project. AcoustiFLO fans are a great fit for projects where energy efficiency and acoustics are paramount. And for a budget-friendly option, our FANWALL EC fits the bill—it's a complete, integrated fan system that is mounted to a bulkhead wall instead of being built from individual fan cells into an array. Finally, PF09 fans make a great choice for tight mechanical rooms and other small AHU cabinets.

Fan Options

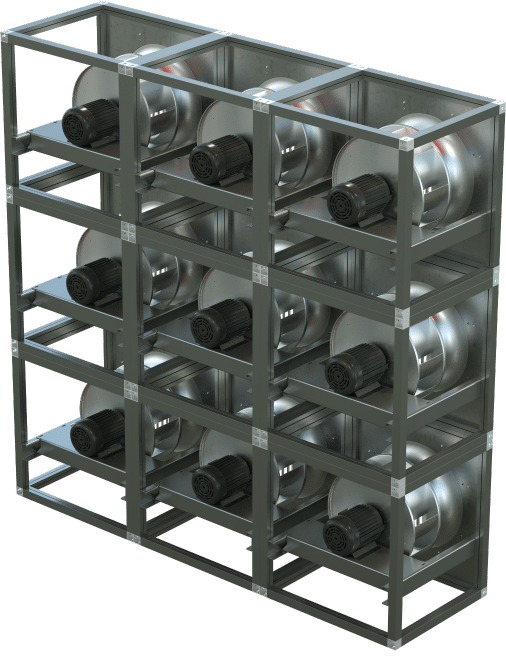

FANWALL Systems

FANWALL systems are ideal for tight mechanical rooms or retrofit projects, reducing air handler length by up to 70% and offering flexible cube configurations to fit virtually any space.

Ultra-high efficiency Permanent Magnet (PM) motors deliver 5%–20% greater efficiency than NEMA Premium® induction motors, significantly reducing energy consumption and operating costs. (Try our interactive payback calculator here).

Each fan-motor pair is equipped with a dedicated Variable Frequency Drive (VFD), allowing precise speed control and isolating failures—ensuring uninterrupted airflow and eliminating the need for bypass VFDs.

The patented Coplanar Silencer® and high-performance polymer fans with aerodynamic shaping and damping materials reduce discharge sound power by up to 18 dB—often eliminating the need for additional sound attenuators.

Direct-drive fans eliminate belts and sheaves, while permanently sealed motor bearings and low vibration construction minimize maintenance and extend system life.

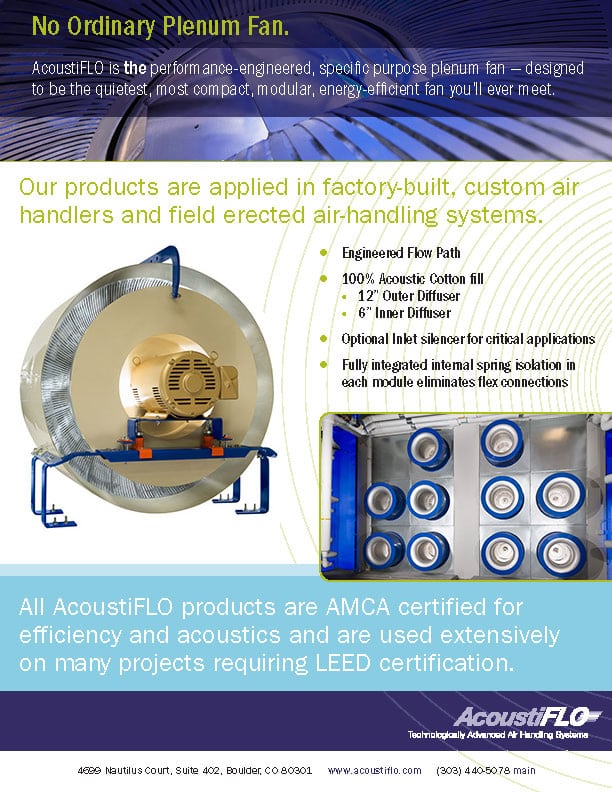

AcoustiFLO

AcoustiFLO fans deliver over 10% higher peak static efficiency than competing plenum fan arrays (AMCA Certified), with real-world applications showing up to 40% energy savings—ideal for projects focused on total cost of ownership and LEED certification.

Engineered for acoustic excellence, AcoustiFLO fans are 10–20 dB quieter than competitors in critical frequency bands (250–500 Hz), often eliminating the need for additional sound attenuators and reducing system pressure drops.

With a reduced aspect ratio and less than one inch between fans, AcoustiFLO systems are compact and modular, supporting vertical, nested, and floor-mounted configurations to fit virtually any custom or field-erected air handler.

Designed for medium to high static pressure applications (6–12 inches), AcoustiFLO fans maintain high efficiency even under demanding conditions, with optional exit guide vanes boosting performance by an additional 2–5%.

Available in three fan sizes (16.5", 27", and 30") with motor options from 3 to 40 HP, AcoustiFLO fans are optimized for airflows from 5,000 to 25,000 CFM, making them ideal for both small and large-scale systems.

FANWALL EC

FANWALL EC is a fully integrated fan system mounted to a bulkhead wall, offering a streamlined, space-saving alternative to traditional fan arrays. It's ideal for value-driven projects and tight mechanical rooms.

Use as a single fan or in multi-fan configurations, arranged in-line or in custom layouts to meet specific airflow and redundancy requirements—perfect for both new construction and retrofit applications.

In the event of a fan failure, remaining fans automatically ramp up to maintain airflow, enabling planned maintenance without compromising system performance or uptime.

Galvanized steel wall panels are engineered with a rigid structural profile to ensure stability and durability during operation, even in demanding environments.

With no belts, sheaves, or greasing required, FANWALL EC is virtually maintenance-free. Simple analog on/off control and BACnet® compatibility make integration and operation easy.

PF09 FANS

Ideal for tight mechanical rooms and other small AHU cabinets over traditional fans.

Provide a great alternative to FANWALL when shorter sections are required, allowing for openings to be placed directly above.

Direct-drive, which eliminates belts and sheaves and the need for greasing. The permanently sealed motor bearings and vibration-free construction minimize maintenance and extend system life.

Each fan-motor pair is equipped with a dedicated Variable Frequency Drive (VFD), allowing precise speed control and isolating failures, helping ensure uninterrupted airflow and eliminating the need for bypass VFDs.

Can be used as a single fan or multiple fans aligned side-by-side as needed to meet specific airflow and redundancy requirements.