Advanced Solutions for Better Building Environments

Nortek Air Solutions offers the expertise of the largest group of custom heating, ventilation, and air conditioning (HVAC) brands in North America. With that level of experience, we take pride in being industry pioneers and leading innovators. It’s our goal to provide you with the best performing, most energy efficient, and most cost-effective HVAC solutions on the market.

Do you have questions about Nortek Air Solutions, our products, or how we can help you solve your next application? Contact us, and we’ll be here to help in any way we can!

Our extensive network of Nortek Air Solutions representatives can also help you think through your building application and develop the perfect solution to meet your air handling requirements.

We’re a pioneer in air handler efficiency that can reduce your energy costs. Our engineering expertise and advanced technology help us develop innovative components and products to provide you with an HVAC system that has optimized energy efficiency for your application.

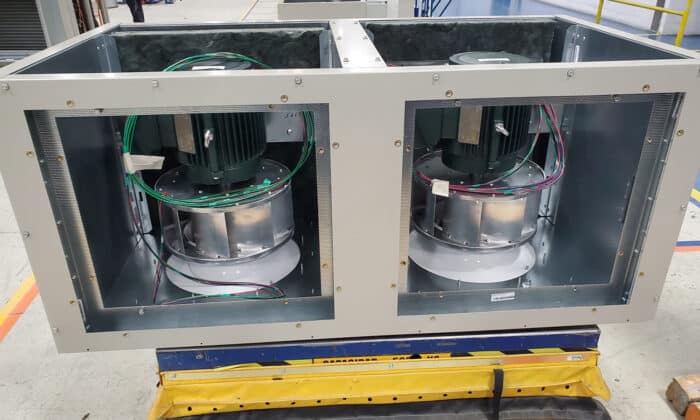

FANWALL TECHNOLOGY — by Nortek Air Solutions brand Huntair — is a patented fan array solution for air handlers consisting of an integrated system of state-of-the-art fans, motors, cabinetry, controls, and accessories matched to your air handling requirements. FANWALL TECHNOLOGY is the preferred choice for engineers, contractors, and building owners who value redundancy, quiet and vibration-free operation, optimized energy efficiency, and low-cost maintenance and service for their new construction and retrofit building projects.

Our innovations in the area of green design enable us to custom engineer HVAC solutions to meet your specific requirements which can contribute points to LEED® building certification.

Our advancements in humidity control, Dedicated Outdoor Air Systems, and filtration can significantly improve the indoor air quality of your building.

Whether you need to replace an aging air handler or fan, require a unique configuration or compact footprint on a retrofit project, or face access and installation challenges, we offer high-performance, efficient solutions for air handler replacement applications, including FANWALL® Systems and Knockdown Air Handlers.

We understand that acoustics are a major consideration for your air handling solution, and many applications require air handlers with low sound levels. Our innovative noise reduction technologies can help you reduce sound levels for comfortable, functional building environments.

Supplying air at the right humidity level is essential to creating comfortable environments. Our innovative humidity control technologies and air handling solutions help you supply comfortable airflow to your building.