Understanding Healthcare Building Challenges

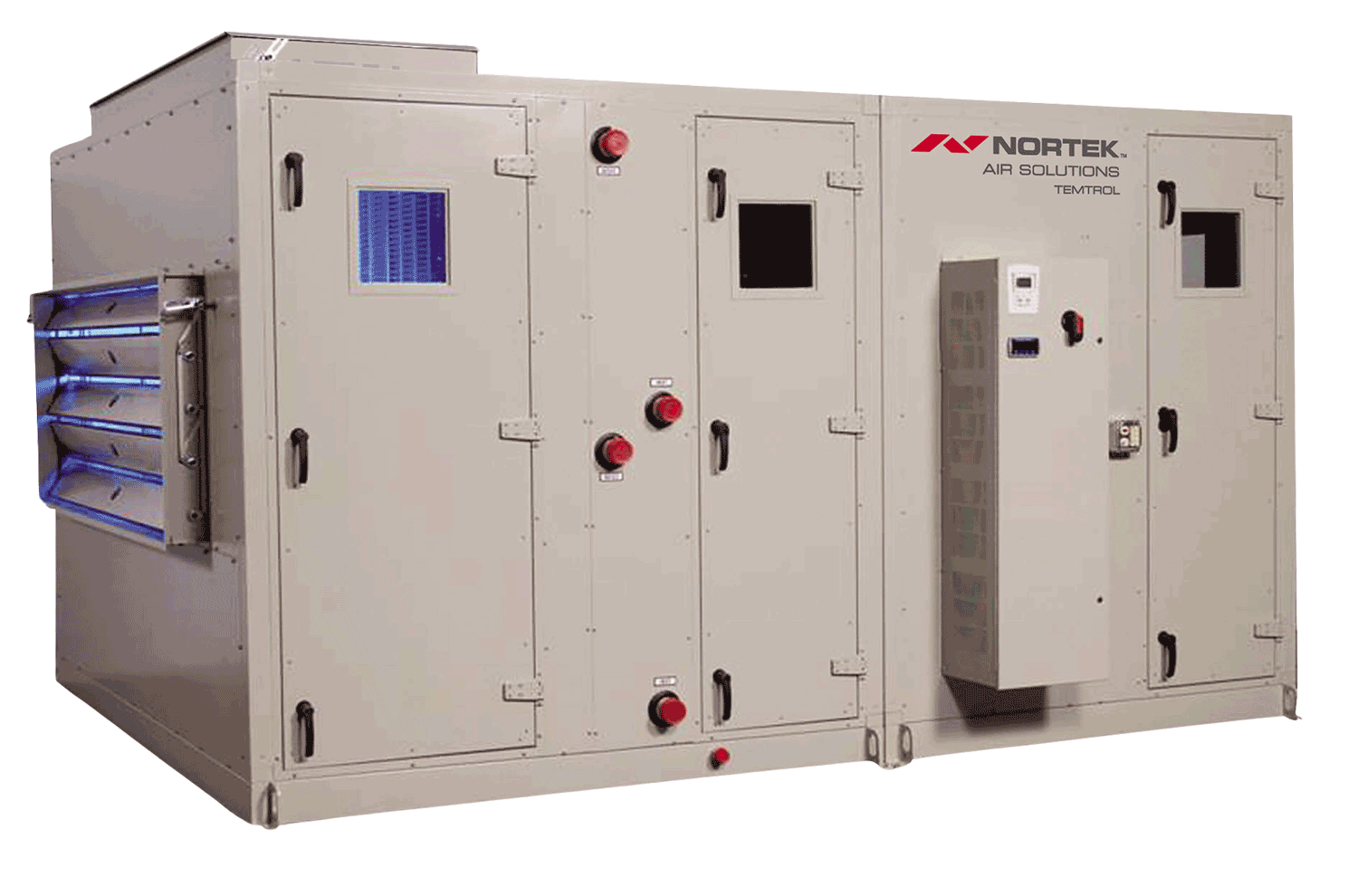

Healthcare facilities face many unique building management challenges due to the critical nature of their operations and the need to ensure patient and employee safety and comfort. These are challenges Nortek Air Solutions can help with. Implementing effective HVAC systems to control air quality, provide patient and employee comfort and reduce airborne pathogens while adhering to stringent healthcare regulations and standards, is a challenge we understand. We invite you to explore ways that Nortek Air Solutions can help you address the challenges you face in healthcare facilities today and into the future.

While the HVAC system is only one component of creating the ideal environment in a healthcare facility, it can represent a major part of the operating budget. And given that many healthcare facilities operate on very tight profit margins while maintaining a 24/7/365 schedule, opportunities to lower operating costs without sacrificing indoor environmental quality can make a significant contribution to the bottom line.

Nortek Air Solutions offers a range of innovative, reliable, high-efficiency custom solutions to help you create clean and comfortable environments for the patients and staff in your healthcare facility.

Understanding Healthcare HVAC Challenges

-

Infection Control

-

Maximize Uptime

-

Energy Management

-

Patient & Employee Comfort

-

Safety & Security

-

Regulatory Compliance

-

Maintenance & Repairs

-

Emergency Preparedness

-

Space Utilization

Maximizing Uptime…

…is particularly important in healthcare applications, where a failure could affect the health, safety, revenue and comfort of patients and staff.

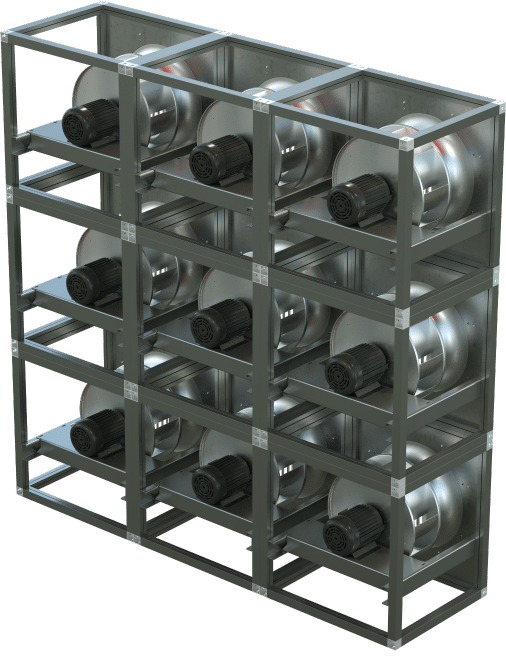

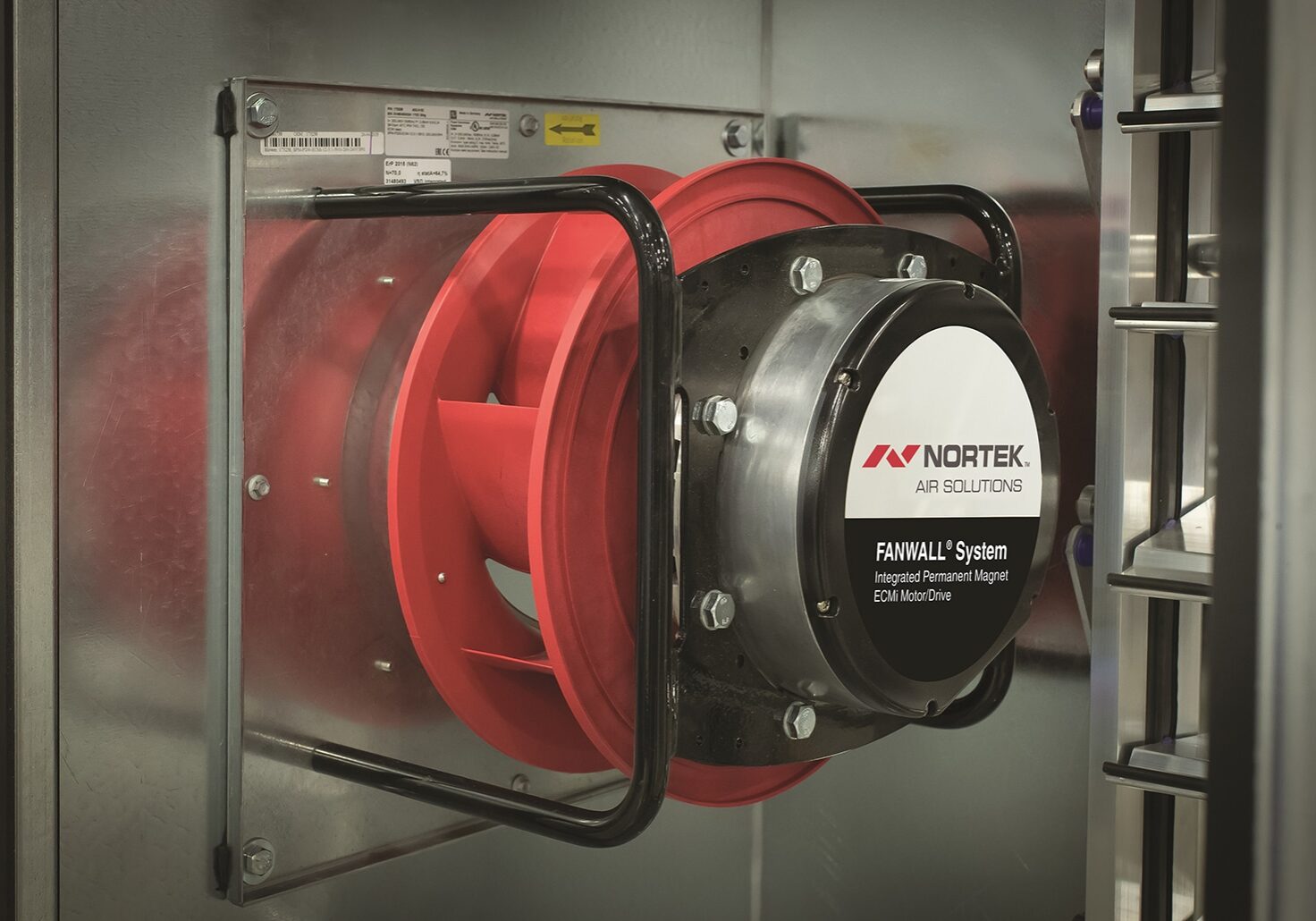

Our FANWALL® systems are designed with reliability in mind. With conventional single fan and motor systems, a failure of either component shuts down the entire air handler system. This creates a critical path failure that requires immediate, costly action. When a fan or motor failure occurs in a FANWALL system, the remaining operating fans can compensate to maintain airflow and static pressure until the failed component can be repaired or replaced.

Design for Long Life…

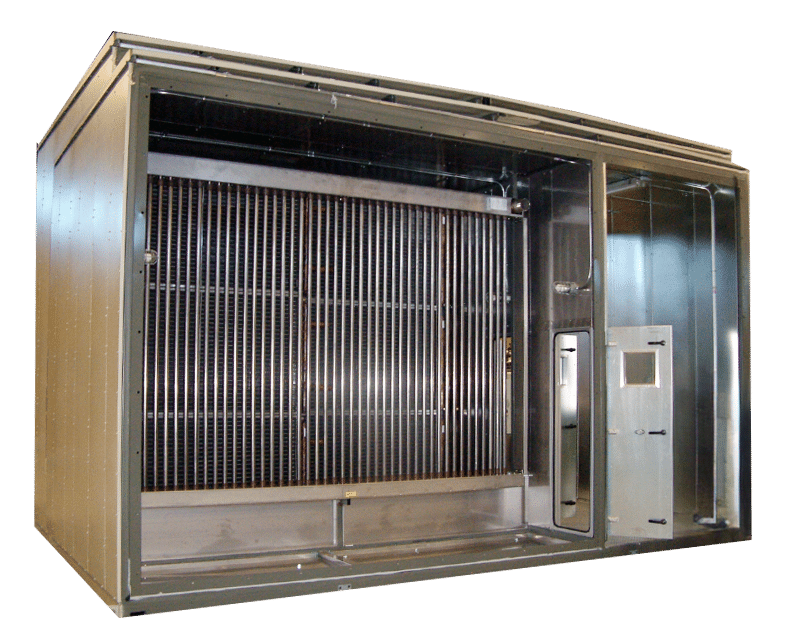

… is often required in healthcare applications for air handling equipment since its location oftentimes has severe egress constraints. Nortek Air Solutions can reduce your life cycle costs by designing equipment with materials that extend the lifespan of the equipment. Materials like aluminum can sometimes double the life of an air handler. Other materials like stainless steel and metal coatings can extend equipment life. Corrosion-resistant materials require less frequent maintenance and repairs leading to cost savings over time.

Energy Management…

…for your facility balanced with occupant comfort requires innovative technologies that allow you to accomplish both. Energy saving features like variable frequency drives, energy recovery heat exchangers (plate, wheel, heat pipe, coil run around loop), high efficiency motors that maintain a high level of energy efficiency at part load conditions, FANWALL system optimization controls that provide smart control on the fans based on building demand, airside and waterside economizers that can provide free cooling when outdoor air conditions are favorable and heat pump technology for both heating and cooling that aids in your decarbonization priorities.

Patient and Employee Comfort…

…is multifaceted, impacting both the quality of care provided and the overall efficiency of the healthcare system. Creating the right environment both thermally and acoustically can improve recovery rates, patient satisfaction, employee productivity and satisfaction and lower turnover rates. Nortek Air Solutions can optimize the conditioning of your air (cool, heat, humidify, dehumidify, clean) and provide assured acoustical performance its equipment.

Humidity Control…

…in healthcare buildings is as essential as temperature control for creating comfortable building environments for occupants and for designing efficient, cost-effective HVAC systems. Proper humidity levels contribute to a comfortable indoor environment for occupants. High humidity can make spaces feel warmer than they are, while low humidity can cause dryness and discomfort. Maintaining appropriate humidity levels helps prevent health issues also.

Our advanced humidity control technologies, available on many of our products, allow you to effectively control the humidity in your building spaces. We offer more coil options than most, so you’ll be able to match your coil to your application needs and help solve even the most demanding of dehumidification applications. Our innovative thermal break technologies prevent thermal bridging and eliminate sweat or frost on your air handler, which can lead to additional moisture in the air. In addition, we offer custom units with Energy Recovery Systems.

Advanced Filtration…

…in air handling systems to control air quality and reduce airborne pathogens is common to most healthcare facilities. Maintaining strict hygiene, sanitation and maintenance standards can help prevent the spread of infections. Nortek Air Solutions provides a variety of advanced filtration technologies to aid in achieving your filtration needs. Technologies like High-Efficiency Particulate Air (HEPA) filters, Ultra-Low Penetration Air (ULPA) filters, activated carbon filters, gas phase filters, medium efficiency pleated filters, high efficiency bag filters and high efficiency rigid filters.

Equipment Safety Certifications…

…support the need for your facility’s air handling system to remain operational during natural disasters. That is why we have invested in equipment safety certifications like HCAI OSHPD, Miami-Dade and IBC. These certifications ensure that our equipment meets high standards of performance and reliability, which is crucial in healthcare settings where air quality can directly impact patient health. They also help facilities comply with regulatory requirements and industry standards reducing the risk of legal issues and penalties.

Retrofit or Replacing

…air handling equipment in healthcare facilities is essential for maintaining operational excellence and ensuring patient health and comfort. Take advantage of the latest energy efficiency improvements and leverage technology advancements to improve unit operation and save energy costs. Nortek Air Solutions can provide solutions for installing equipment inside your facility with minimal disruptions or expense. Our knockdown unit construction enables you to bring in new products or components either by the piece or section. We can provide factory training to those installing new equipment so the changeout can happen efficiently.

Decarbonization Strategies…

… for air handling equipment in healthcare facilities often focus on reducing greenhouse gas emissions and improving energy efficiency. Nortek Air Solutions can help you with energy efficiency improvements, geothermal energy and air source heat pump options for heating and cooling, and the use of low GWP refrigerants to reduce the environmental impact.