High-Efficiency, Flexible Retrofit & Upgrade Solutions

An upgrade or replacement of your inefficient or unreliable HVAC equipment offers you significant energy savings and improves sound levels, indoor air quality, and reliability as well as the net operating income and value of your building asset.

Nortek Air Solutions has a long tradition of developing innovative air handler retrofit and replacement solutions that are reliable, efficient, high performance, and perfect for solving installation challenges and space constraints with minimal disruption to building occupants or processes.

Understanding Retrofit & Upgrade HVAC Challenges

-

Funding

-

Downtime

-

Energy Efficiency

-

Space Constraints

-

Disruption to Occupants

-

Time Constraints

-

Building Codes & Standards

-

Maintenance and Training

-

Long-Term Sustainability

Transformative Power of Air…

…is what we believe in at Nortek Air Solutions. Every day, each of us breath 23,000 times. As much as we depend on air, it is often the one most taken for granted. For the nearly 2,000 passionate entrepreneurs at Nortek Air Solutions, it’s at the heart of everything we do. We believe in the transformative power of air and creating a safer, healthier, and more productive world together.

Retrofit and Replacement …

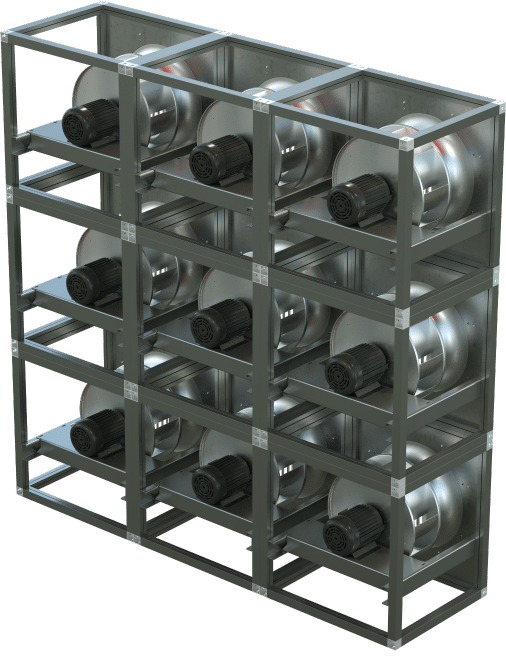

… of old air handlers or end-of-life fans systems is much easier today using a FANWALL System from Nortek Air Solutions. It can be the most cost-effective solution for avoiding business disruption of an air handler failure, while delivering energy saving improvements as high as 40%.

In many cases, fan or air handler replacements have access limitations that require the time and expense of a major demolition and reconstruction project. A FANWALL system can minimize this and other barriers.

The performance of the new system can be optimized to match actual capacity and airflow requirements. Ancillary components that created static-pressure penalties in the old system can be removed, such as sound attenuators and air blenders.

Retrofits often can happen over a weekend or during unoccupied timeframes to minimize downtime or disruption of normal business. Many of the components of a fan retrofit can fit in a standard elevator or through a three foot wide door. We’ve engineered 1000’s of FANWALL retrofit solutions and have developed best practices in our solutions.

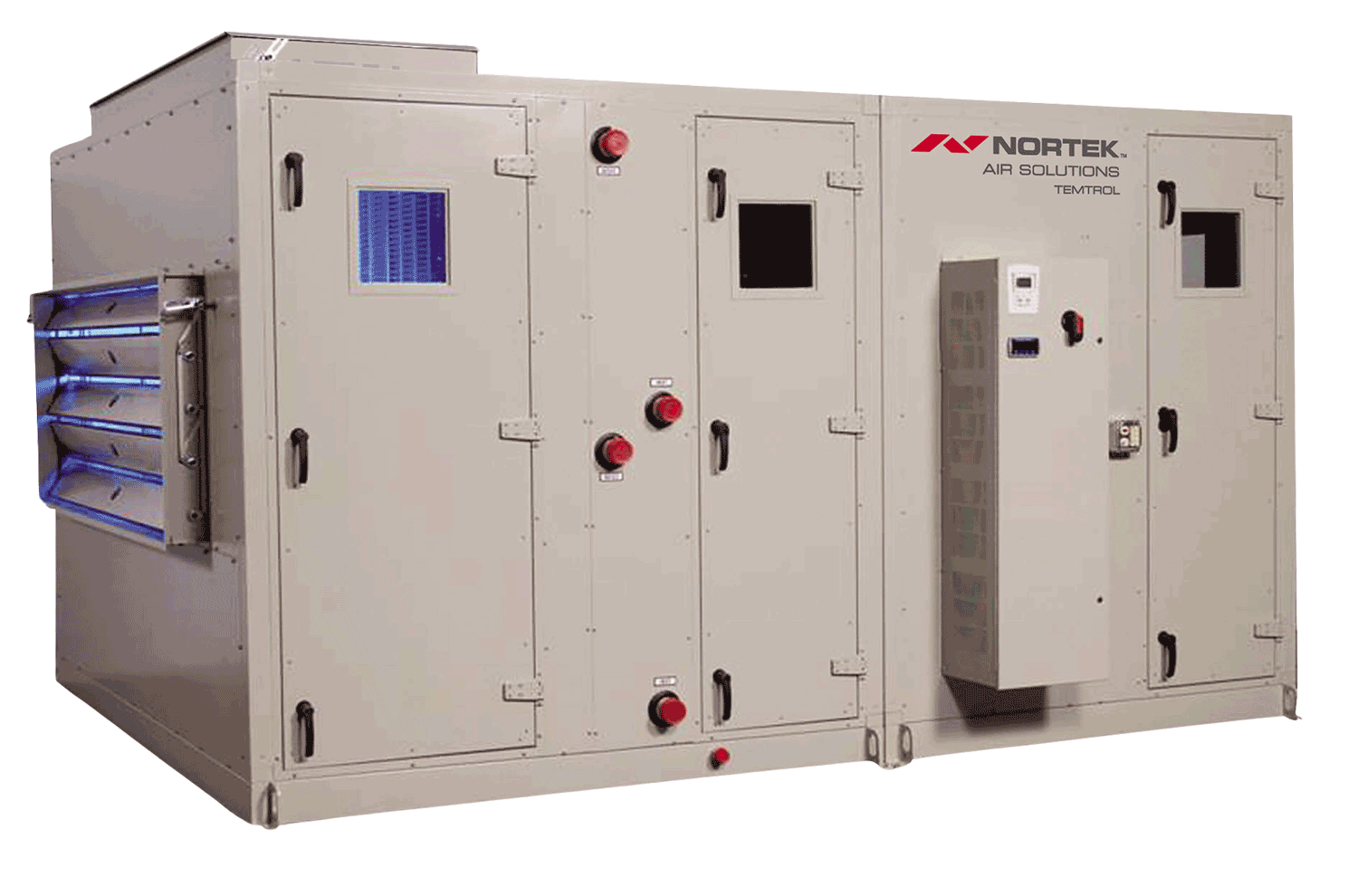

Replace Packaged DX…

…units with our innovative Mammoth V-Cube™ Slim unit that can break apart on the jobsite to allow for easily transport into the building without expensive demolition. And the refrigeration system remains in tack and charged.

The V-Cube Slim knockdown solution is designed to be a quick solution for replacement of existing floor-by-floor units. The packaged design, complete with a standard VFD and optional factory-integrated communication controls, reduces field labor. A compact footprint allows easy replacement of existing units manufactured by others. Built-in electrical disconnects reduce field labor and installation costs.

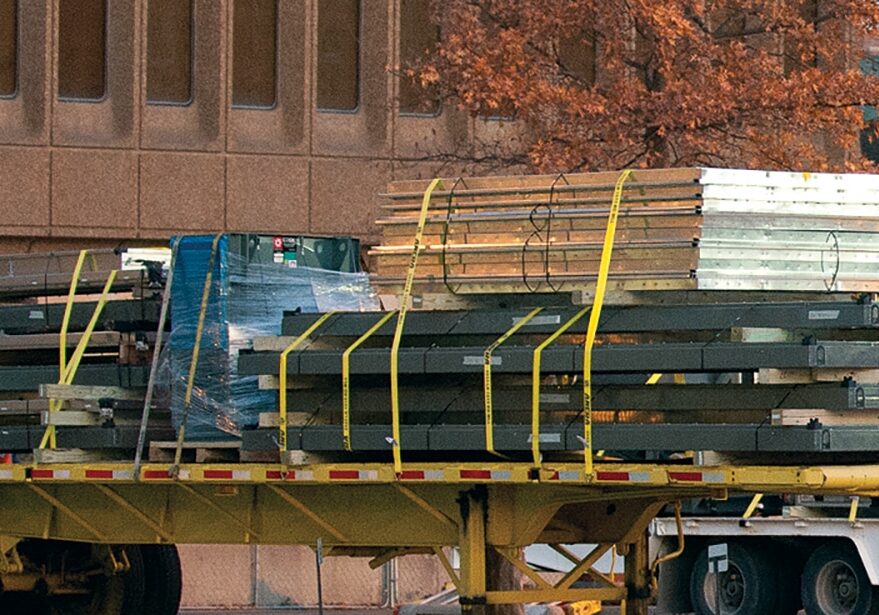

Palletized Air Handlers…

…are another way we deliver air handling solutions for upgrading existing systems. Unit are assembled complete in the factory and then disassembled and palletized into sequenced groups. All hardware and sealants are provided with the unit.

Architectural Finishes…

..to match your building’s finish and surroundings is a sophisticated way of blending your HVAC with your building’s architecture. Custom paint colors is another option.

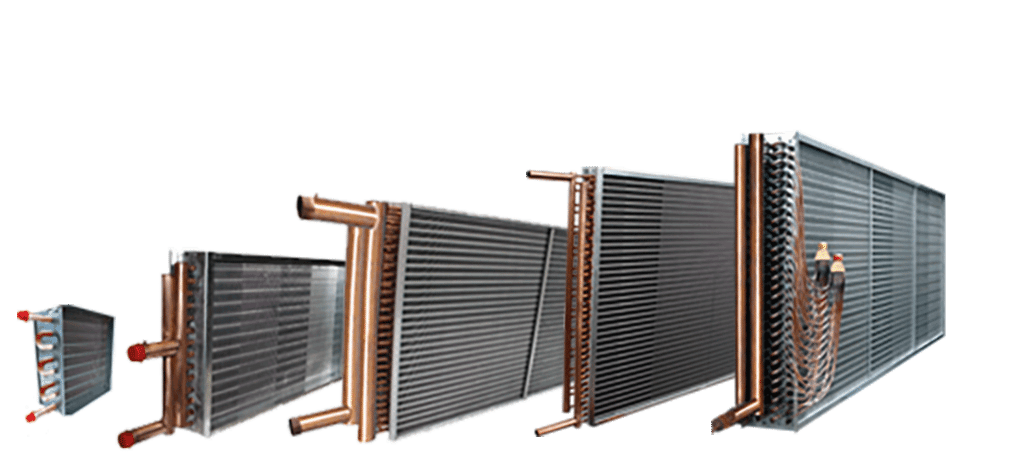

Heating and Cooling Coil…

…exact replacements is what we do. Since 1955, we’ve been committed to manufacturing all our coils using the highest quality materials and strict quality control standards. Our commitment to quality ensures a long product life and top performance. And our quick-ship options mean you’ll get your coils when you need them. Nortek Coils Solutions offers a wide range of coils in custom sizes and materials:

- Evaporator coils

- Hot water booster coils

- Standard steam coils

- Chilled water coils

- DX coils

Whether you need replacement coils in weeks or just days, you can trust Nortek Coil Solutions to deliver a solution on time and on spec.